Innovation and Industry

Engineering Equipment Company

With more than 50 world-first’s our engineering and research teams can be depended upon to deliver Innovation + Industry

100+

Years of global innovation,

growth and partnership

50+

World-firsts

and patents

82%

Of our machines are

exported globally

75%

of apprentices spend over

10 years within the business

Innovation and Industry

With more than 50 world-first’s our engineering and research teams can be depended upon to deliver Innovation + Industry

100+

Years of global innovation,

growth and partnership

50+

World-firsts

and patents

82%

Of our machines are

exported globally

75%

of apprentices spend over

10 years within the business

+ Over 100 years spent in the relentless pursuit of quality, innovation and reliability.

We are Emerson and Renwick, known to many as E+R, a privately owned, independent equipment engineering company.

The company has grown and developed across a number of market sectors and is positioned as a leading manufacturer of sophisticated roll-to-roll production machinery.

We have built a reputation for engineering, technology and process innovation and use the experience gained across a hugely diverse range of applications to support developments for ever more demanding processes and products.

Innovation lies at the heart of everything we do, whether creating new enabling technologies or refining processes to enhance capabilities and productivity. When needed we work with strategic partners to integrate sophisticated and complex source technologies to our platforms.

E+R has achieved growth into new marketplaces by diversification and by embracing new and developing technologies and secured its position within existing markets with the innovation of products and processes.

A key factor has been our success in the recruitment and development of highly skilled technical personnel across a wide range of capabilities and competencies.

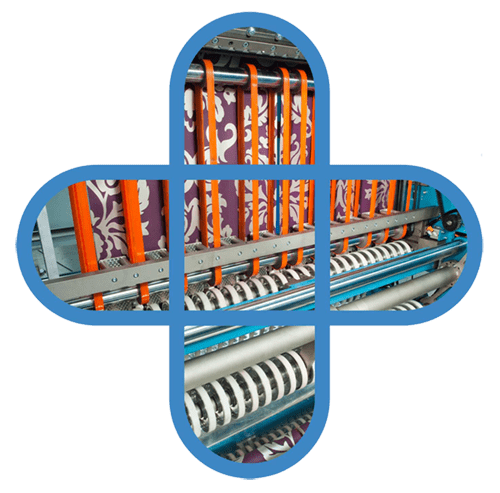

+ Manufacturers of Printing and Coating machines for the printing, wallpaper and wallcovering industries.

E+R have a long history in the sector and an extensive portfolio of machines for all Wallcovering processes and manufacturing techniques.

We continue to develop advanced printing and coating machines for worldwide application in the printing, wallpaper and wallcovering marketplace.

Much of our output is bespoke, highly innovative and built to the specific requirments of the clients. We're always working to develop ideas and trends, keeping E+R at the forefront of wallpaper technology.

+ Heat Exchanger Technology, Tube Mill, Fin Mill and Core builder machines for automotive applications and beyond.

Our experienced and dedicated team include designers, engineers, creative problem-solvers and critical thinkers who are committed to creating the best possible solution for your project or challenge.

Our significant FMEA expertise can help assist you:

• Reproduce any existing FMC machinery

• Re-Tool all existing FMC machinery

• Supply Spares for all existing FMC machinery

• Upgrade all existing FMC machinery

Creating new technology and applying this to the machinery we produce is our key focus as this is what gives our clients a significant competitive edge.

+ The perfect Coating & Laminating equipment solution, whatever your industry.

At E+R our first priority is always gaining a complete understanding of our your requirements and processes and to apply that knowledge to creating a solution to meet or exceed your technical and commercial expectations.

We will apply many years of experience and expertise in coating application systems, drying and web handling technologies and use our creative thinking to develop new techniques.

Our well-equipped and professionally staffed R&D facilities are available to those who come to us with new and emerging products in order for both sides to gain important knowledge of the optimum production techniques and conditions.’

+ Commercial Vacuum coating equipment built to your specification

Vacuum coated products play a role in our every day lives. E+R understand the need to ensure our products allow our customers and partners to remain at the forefront in their target markets.

With a highly experienced team in vacuum coating technology, it allows the E+R Group to offer flexible, market leading solutions to address market changes, throughput and economic improvements and ultimately increase the value added potential for our clients to their own product portfolios.

With an ever expanding portfolio of application knowledge, we apply this to the machinery we produce to ensure we meet the needs of the ever changing markets we serve.

+Total service solutions

Productivity takes more than a best-in-class machine. Because we know your machine better than anyone, our maintenance solutions providing condition-based monitoring and preventive maintenance management will help you minimize downtime, maximise performance and protect your investment through proactive maintenance executions.

+ Spare Parts & Consumables

E+R is totally committed to providing the best spare parts and consumables, remanufactured by us and delivered to your site as quickly as possible.

+ Relocations

You may need to move your E+R machines, perhaps a few feet, perhaps a few thousand miles.

You can count on us to take care of everything, giving you turnkey reinstallation of your machines.